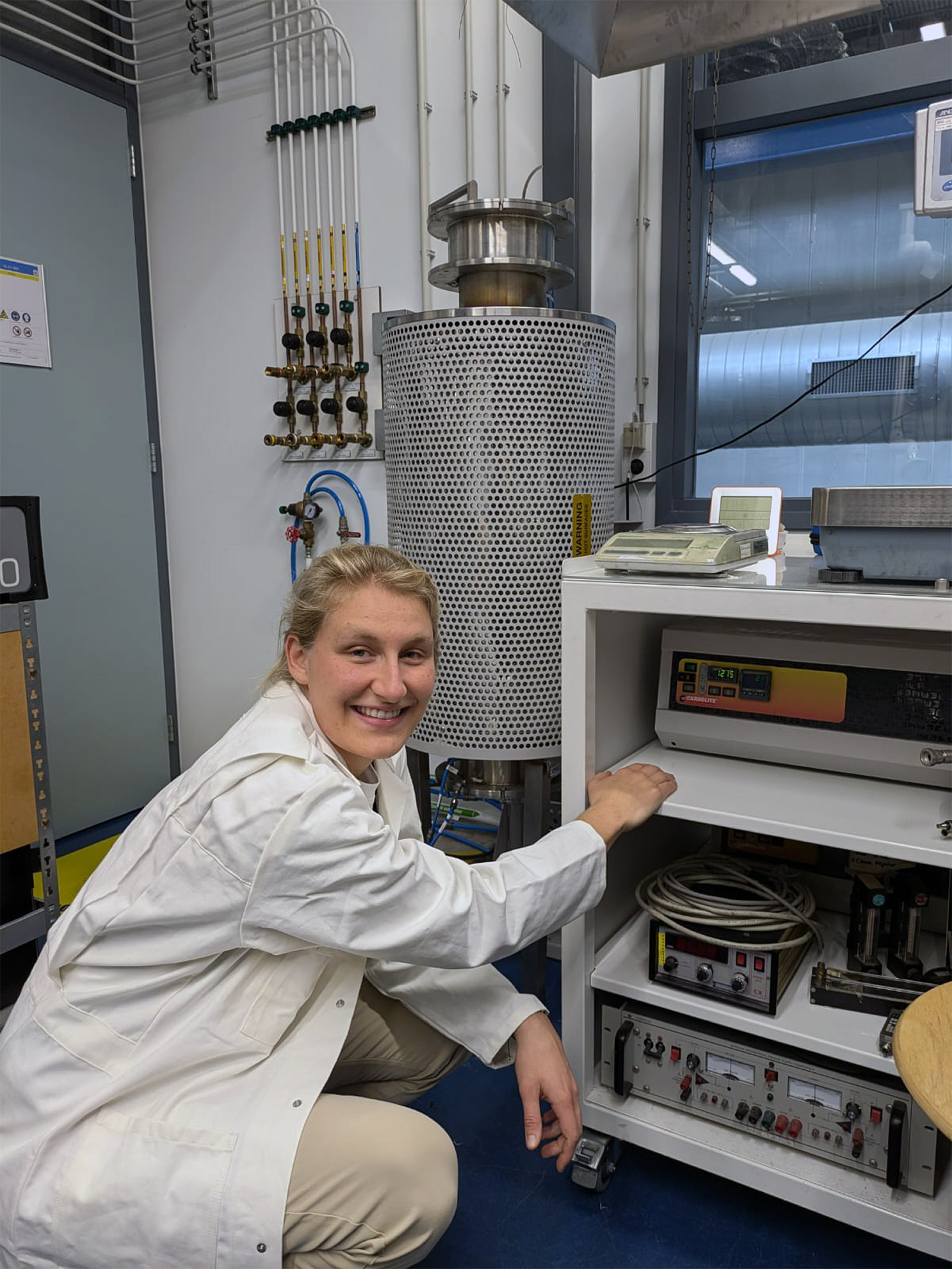

Hannah Weber is a doctoral researcher from TU Delft. Her project HELIOS is funded by Marie Skłodowska-Curie Actions and her work in this project as DC1 focuses on the reduction and degradation of pellets in a hydrogen-dominated direct-reduction shaft furnace.

1. Hello Hannah, thanks for agreeing to this interview. Could we start with your background. What kind of work and study were you involved in prior to joining the HELIOS project as a Doctoral Candidate?

Before joining the Helios doctoral network at TU Delft, I completed my bachelor’s and master’s degrees in Recycling Technologies, focusing on metal recycling, at Montanuniversität Leoben in Austria. During my studies, I had the opportunity to work as a student assistant at the Chair of Nonferrous Metallurgy. This included working on many pyro- and hydrometallurgical projects, which are important for primary and recycling industries. Prior to my university education, I attended a technical high school program in industrial engineering with a focus on technical design. After graduating from technical high school, I worked as a technical designer in Canada for one year.

2. What inspired you to apply to join the HELIOS Doctoral Network.

As mentioned, I had the valuable opportunity to work as a student assistant at the Chair of Nonferrous Metallurgy while studying. During this time, I participated in various research projects, many of which were closely linked with industry. This experience allowed me to contribute to innovative solutions for handling and reducing residues produced during industrial processes, sparking my passion for pyrometallurgical processes. Through this experience, I gained deep insights into recycling technologies, but also came to understand that in addition to focusing on recycling, we need to make primary metal production more environmentally friendly. Currently, the available amounts and quality of scrap are insufficient to meet the future demand for producing all new products solely from recycling. After graduating, I came across the Helios Doctoral Network, which aims to make the primary production of iron and steel more sustainable by the adoption of hydrogen in metallurgical processes. Therefore, I decided to apply for the position DC1, which focuses on the reduction and degradation of iron ores in a shaft furnace using hydrogen as the main reductant and energy source. It has always been important to me to choose a meaningful career path where I can contribute to a more sustainable future and simultaneously continue to learn new things.

3. Can you tell us about your research project? I read that you work investigating complex reduction and in-situ carburization phenomena. Can you explain what it is that you are researching?

Currently, the production of iron and steel is dominated by the reduction of iron ores in blast furnaces, followed by the refinement in basic oxygen furnaces. While efficient, this traditional route heavily relies on fossil fuels and in particular carbon, producing a significant 7–9 % of anthropogenic-caused CO2 emissions. Our research focuses on a promising new pathway: the direct reduction of iron carriers in a shaft furnace, which operates using hydrogen as an alternative to carbon-based reduction and energy source. Although the utilization of hydrogen drastically reduces CO2 emissions, there are many technical challenges that come with this transition. My research aims to better understand the phenomena that occur while replacing carbon (coal and coke) with hydrogen. Therefore, important parameters that are affected by enriching the hydrogen content and completely replacing carbon, like degradation, reduction, and in-situ carburization, need to be further investigated to guarantee an efficient future process. Furthermore, high-grade iron ores are depleting, and therefore, we are looking for solutions to use blast furnace grade ores and alternative lower-grade input materials.

4. Your project is taking place at TU Delft. How are you finding the university and your life in the Netherlands?

I feel very fortunate to have the opportunity to work at TU Delft and live in such a beautiful country. TU Delft offers an excellent research environment with brilliant minds in the field, which is truly inspiring. While moving to a new country is very exciting, it also comes with its challenges, of course. Finding housing was quite tricky, but my colleagues and members at TU Delft were incredibly supportive throughout the process. Adjusting to life in the Netherlands has been a very enriching experience, and I am enjoying exploring the culture and making the most of my time here.

5. You have been part of the HELIOS project for about half a year now. How are you enjoying being part of a team of 10 PhD researchers, all working towards a common goal?

5. You have been part of the HELIOS project for about half a year now. How are you enjoying being part of a team of 10 PhD researchers, all working towards a common goal?

Although I have only been part of the Helios project for approximately five months, it has been an incredible and rewarding experience. What fascinates me most about the Helios network is the collaborative nature of the project. Universities and industry partners from all over Europe, including doctoral candidates, are working together rather than competing against one another. By collaborating, we can achieve far more innovative solutions. I believe that current challenges, such as climate change, can only be solved if we work together as a community, and this network is a perfect example of how collaboration can drive progress.

6. Do you find that your experiences in industry, in Austria and Canada, are proving useful now you are involved in a more "academic" atmosphere of doctoral studies?

Yes, very much so. My previous work experience not only helped me discover my true passion but also equipped me with several valuable skills. These skills come from personal experiences, which no textbook teaches you. I would encourage every young person to try out many different things and seize opportunities that arise. Every new experience and challenge contribute to personal growth. I have been very fortunate along the way and have always encountered people who encouraged and supported me when needed.

7. What would your advice be to someone who was thinking of doing a PhD as part of a Marie Sklodowska-Curie Action?

I would most certainly encourage people to apply. So far, it has been a fantastic experience for me, and I’m looking forward to many more in the coming years. Besides that, I believe we will need a lot of talented and motivated people who work and focus on problems that our society is facing. These networks are a great opportunity to be part of this change.

8. Do you have any thoughts about your future? Do you see yourself as a "scientist", or do you plan to move into another profession?

I don’t know what opportunities may come up in the future. While I find working in academia fascinating, particularly due to the variety of projects and the opportunity to continuously learn from others, I also recognize that a career in academia can be very demanding and sometimes uncertain when funding, for instance, is not always guaranteed. Therefore, I have a lot of admiration for those who have pursued an academic career. I also strongly believe that it’s essential to bring scientific solutions and findings into industry that benefit environmental protection and address climate change challenges.

9. How can we encourage more young people to choose a career in fields of metallurgy, mining, material science, recycling etc. ?

I believe we can encourage young people to pursue a career in these technical fields by promoting and explaining their significance more openly. From a very young age on, we are taught why professions like doctors, dentists, lawyers, and furthermore are important, but we rarely learn about the critical role of engineers in the fields of materials and metals. Metals are extracted from ores or produced by recycling and play a critical role in everyday life and the prosperity of a society. They are essential for infrastructure, transportation, the renewable energy sector, and even medical tools used by doctors. Moreover, these industries hold tremendous potential to reduce greenhouse gases and emissions, which drives us towards a more sustainable future. If we can highlight the impact and importance of these fields, I believe we can inspire more young people to choose these rewarding career options.

10. You chose to study Recycling Technologies. Why did you choose this path and what exactly did you learn in your studies?

I always had many different interests, but I was certain that I wanted to pursue a meaningful career where I could contribute to a more sustainable future by developing innovative and sustainable processes. Studying recycling technologies allowed me to not only learn about ways to minimize, handle, and treat municipal waste but also industrial waste streams, which accumulate in far greater quantities. For example, every ton of primary produced aluminum creates 2 to 3 tons of red mud, an industrial residue that is still mainly landfilled. I am very glad you asked this question, because people often think of recycling in terms of everyday items like plastic bottles or batteries, because of course we use them in our daily lives. We aren’t always aware of industrial by-products that mostly go unrecycled. Few know that the iron and steel industry, by mass, is the largest recycling industry in the world. My studies gave me insight in these lesser known yet crucial areas and have equipped me with a broad knowledge in metallurgy, environmental science, waste management, process engineering etc. I hope we can encourage lots of people to choose these areas as a future career.

SIM² KU Leuven is the KU Leuven Institute for Sustainable Metals and Minerals (SIM² in short). SIM² is one of the official KU Leuven Institutes that were endorsed by the KU Leuven Academic Council. SIM² has more than 370 members, coming from a wide range of (interdisciplinary) research groups and departments at KU Leuven. SIM²’s missions is “to develop, organise & implement problem-driven, science-deep research & future-oriented education, contributing to the environmentally friendly production & recycling of metals, minerals & engineered materials, supporting (…) a climate-friendly, circular-economy”.

• Read more in this featured article in Geniaal.

• Follow SIM² on LinkedIn

• Interviews with other SIM² colleagues and collaborators